Scholars learn about role of science & engineering at Banja Luka brewery

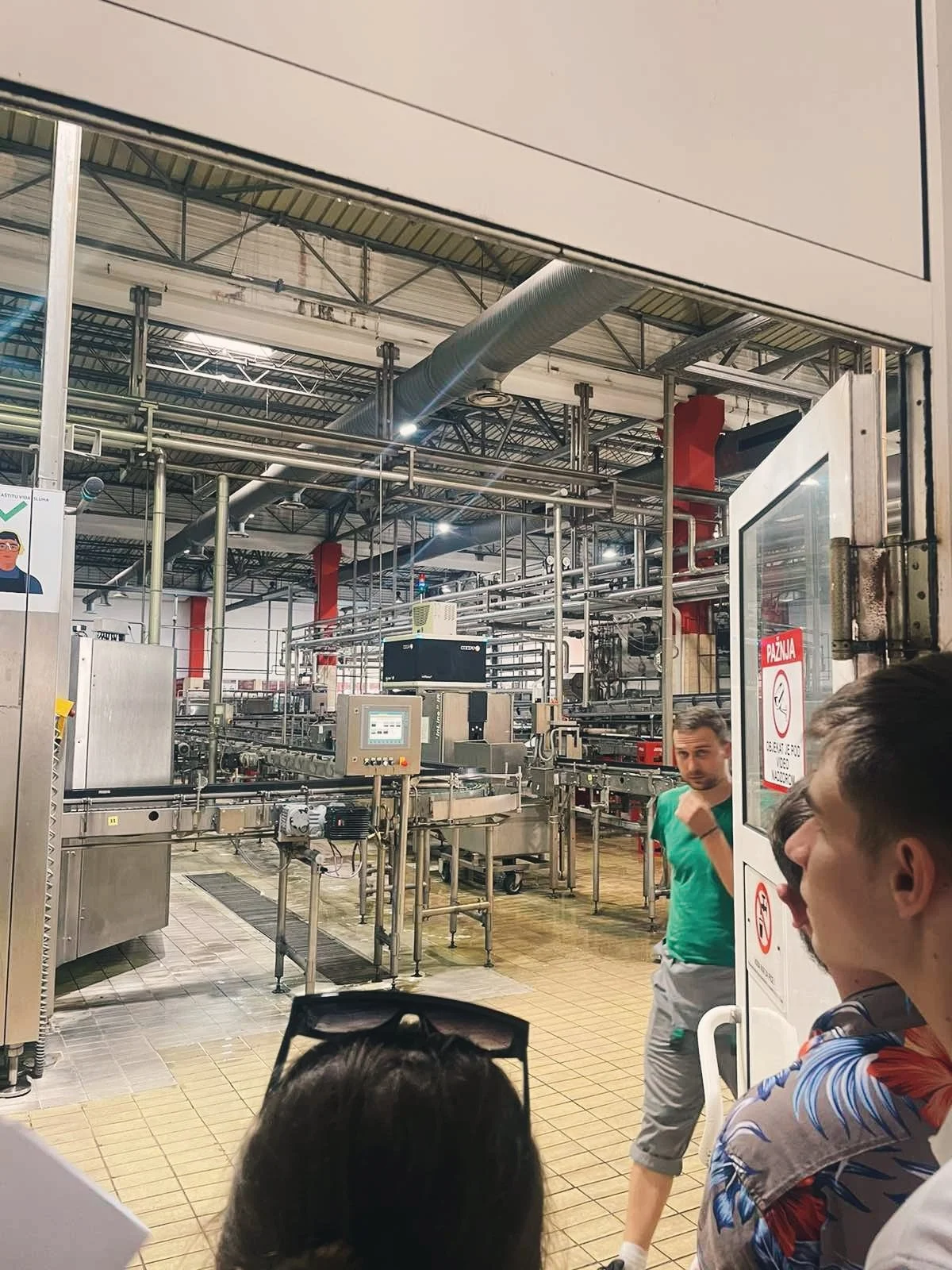

Our scholars visited Banjalučka Pivara to learn about the science, engineering and operations of a modernised large scale production facility.

Founded in 1873 by the Trappists (Catholic religious order), the brewery was known for its famous cheese, but also for the beer they brewed. In the beginning, it was used for therapeutic purposes for the treatment from excessive brandy consumption.

The beer is made from barley, water and hops. Everything is mixed in the variator until the wort is obtained, which later goes to the cooling and fermentation process.

After cooling to 0°C, the fourth essential element is added - yeast. The brewery produces its own yeast in a laboratory, which is different from baker's yeast. The fermentation process lasts 28 days, where the beer is cooled and then goes to filtration.

The entire process is automated, managed via computer, ensuring the stability and quality of our beer.

The bottling plant has four filling lines: bottles, barrels, cans and PET bottles, with a capacity of 40k bottles per hour. The brewery produces 500k hectoliters per year and employs 250 workers. The brewery has been seriously modernised recently and has expanded it's market share.

BH Futures Foundation scholarship holders visited the brewery as part of the foundation academy in Banja Luka to learn about engineering and the science behind beer production.

We would like to thank all the staff at the brewery. In particular Milka Stanivukovic and our friend Ilija Setka aka "The Beer King" for facilitating everything.